Industries: Metal

Metal Handling

Hybrid “HX” End Effectors for 5+ Axis Robots

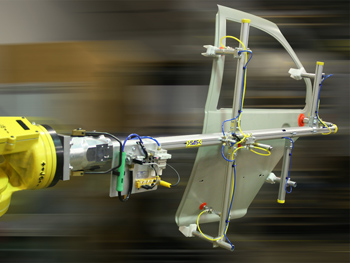

>SAS< Automation recently introduced new Hybrid “HX” End

Effectors for 5+ Axis Robots, made exclusively with the newly developed >SAS< HX hybrid frame profiles and modular off the

shelf gripper components.

This HX profile line is ideal for 5+ axis robots in multi-task, high-speed, heavy weight, or press tending applications.

This new HX End Effector is specifically designed for increased flexibility, offering an optimal “hybrid” design that includes the

benefits of tubular frame adjustability as well as extruded channel frame profile rigidity. Robotic production use includes long reach

boom press tending applications, heavy-duty material handling, or multi-task applications.

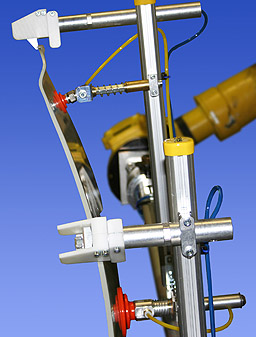

Significant features and benefits: 1 .Direct side channel mounting of standard >SAS< gripper component hardware, eliminating rotation or twist problems.

|

|

This HX line was designed to used with >SAS< GWP-X and PL-X channel nut profiles. The HX’s flexibility and adjustability allows for better routing of pneumatic hoses and electrical sensor wires to grippers and suction cups as well as many other necessary applications. Several connectors EVC and EVH are recommended for the HX profile when connecting in a rigid, perpendicular configuration. The EVC allows for connection of cross connections when the same frame size profile are used; whereas the EVH is used when a smaller cross connector step down in frame profile size, from the larger one. |

|

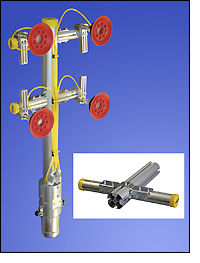

Boom-type Robots For boom-type mounting of robots, the tool side bayonet chucks are offered that clamp directly onto the 40 or 60mm OD. A bayonet is also offered with SAS’s unique D shape frame profile, having 6 mounting surfaces and 7 nut channels. |

|

Press Tending Applications In some press trending applications, vacuum cups on spring compliance mounting arms are necessary, especially when gripping from a flat steel stack to load the stamping die to a formed part removal mode. In this case, simple placement of the spring loaded cups may be adequate; whereas other more complex applications may require indexing or movable end effector configurations that are different for die loading and unloading after the part is stamped and formed in the production line. |

|

| Safety Hold Down Clamps |

For high speed, high weight load applications, or a high level of man machine interface – where safety is an issue (an automotive assembly line), SAS’s GRF Gripper Finger Clamps (safety hold down clamps) are recommended. These are available with protective guides (ZTS) as well as an adjustable back-up stop (ANF). For a fail safe operation, a check valve can be added to ensure that the hold down clamp will continue to grip the part in the event the compressed air supply drops out momentarily or completely fails.

Whatever your application, the >SAS< team is ready to provide superior end effector solutions in a timely, cost effective manner, assuring customers obtain ultimate value and service for your production operation.

"The HX's flexibility and adjustability is ideal where 5+ axis robots are used in multi task applications. Recent successful 5+ axis robot applications have made possible with SAS's HX Hybrid profile system which allows boom end mounting to take advantage of the greater range of applications with these types of robots such as part trimming, deflashing, and other post mold operations, including assembly and packaging," said Trent Fisher, President of >SAS< Automation. "Additionally, it's interchangeability with all of SAS's modular EOAT line of components makes this one of our premier profiles," he added.